In the world of electrical connectivity, where precision and safety are paramount, Morek’s Universal Terminal Blocks for copper and aluminium shine as a beacon of excellence. These versatile OTL (Overhead Line) terminals are engineered to meet the highest standards and cater to a wide range of applications. In this comprehensive guide, we’ll delve into the intricacies of Morek’s Universal Terminal Blocks, exploring their features, certifications, and why they stand head and shoulders above the competition.

Designed for Copper and Aluminium Conductors

Morek’s OTL Universal Terminal Blocks are specifically designed to accommodate both copper and aluminium conductors. This adaptability is a game-changer, as it simplifies inventory management and ensures compatibility with a wide array of wiring scenarios. Whether you’re working with copper or aluminium conductors, these terminals have got you covered.

Cross-Sectional Versatility

One of the standout features of the OTL Universal Terminal Blocks is their remarkable compatibility with conductors of various sizes. These terminals can handle conductors with cross-sections of up to 240 mm², making them suitable for a vast range of applications, from residential to industrial. This versatility significantly reduces the need for multiple terminal types, streamlining your electrical projects.

Wiring Connectivity

To ensure seamless wiring, Morek provides a comprehensive table of universal terminals OTL wiring connectivity options. This invaluable resource aids installers and electricians in making the right connections quickly and efficiently. It’s the kind of attention to detail that sets Morek apart in the industry.

IP20 Protection Class

Safety is paramount in electrical installations, and Morek understands this perfectly. The OTL Universal Terminals boast an IP20 protection class, safeguarding against dust and foreign objects. This level of protection ensures that your electrical connections remain secure, even in challenging environments.

Ensuring Safety and Reliability

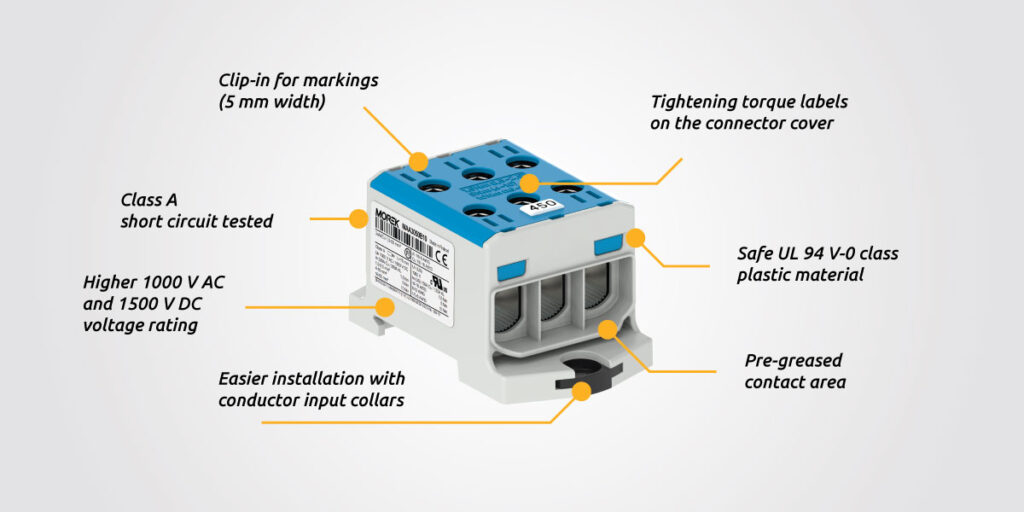

Class A Certification

Morek’s OTL Universal Terminals are certified as Class A connectors, underlining their exceptional durability and ability to withstand short-circuit events. When choosing a connector for your electrical project, always prioritize Class A connectors for peace of mind.

Premium Housing Material

The housing of Morek’s OTL Universal Terminals is crafted from self-extinguishing UL 94 V-0 class plastic material. This material is not only flame-resistant but also exceptionally durable, ensuring that your electrical connections remain secure in all conditions.

Look for CE and Class A Markings

When selecting a safe and reliable connector, it’s essential to check for specific markings. Always ensure that the terminal is equipped with the CE mark and the Class A designation, accompanied by the symbol of the certifying institute, such as FI -mark. These markings are your assurance of quality and safety.

Meeting Stringent Standards

When it comes to electrical components, adhering to international standards is non-negotiable. Morek’s Universal Terminals OTL goes above and beyond by being tested and certified by the following standards:

EN 60947-7-1:2009

Low-voltage switchgear and control gear – Part 7-1: Ancillary equipment – Terminal blocks for copper conductors

This standard guarantees that the terminals are not just functional but also compliant with safety regulations.

EN 61238-1:2003

Compression and mechanical connectors for power cables for rated voltages up to 30 kV (Um = 36 kV) – Part 1: Test methods and requirements

This certification ensures that these terminals can handle high-voltage applications with ease.

Critical for Switchgear and More

It’s crucial to note that all connectors used inside switchgears or similar appliances must meet these stringent requirements. Morek’s commitment to compliance ensures that their products can be seamlessly integrated into a wide range of electrical systems

Class A vs. Class B Connectors

EN 61238-1:2003 classifies connectors for copper and aluminium cables into two categories: Class A and Class B. Understanding the distinction is vital for choosing the right connector for your specific application.

Class A Connectors (Heat Cycle and Short-Circuit Tested)

Class A connectors are designed to withstand short-circuits of relatively high intensity and duration. They are the go-to choice for electricity distribution and industrial networks where short-circuit events may occur. Morek’s OTL Universal Terminals proudly belong to this category, making them suitable for a broad spectrum of applications.

Class B Connectors (Heat Cycle Tests Only, Not Short-Circuit Tested)

Class B connectors are intended for networks in which overloads or short-circuits are rapidly cleared by protective devices like fast-acting fuses. While they have their place, Class A connectors like Morek’s OTL terminals offer a higher level of reliability and safety in demanding scenarios.

When it comes to your electrical projects, trust Morek’s OTL Universal Terminals to deliver unmatched performance and peace of mind. Say goodbye to compatibility issues and subpar connectors—opt for Morek’s Universal Terminal Blocks, the gold standard in the industry.